What is HDD?

Instead of tearing up roads, rivers, railways, or buildings, Horizontal Directional Drilling (HDD) crews drill a controlled underground arc, then pull the pipe through that hole.

How it works (three steps)

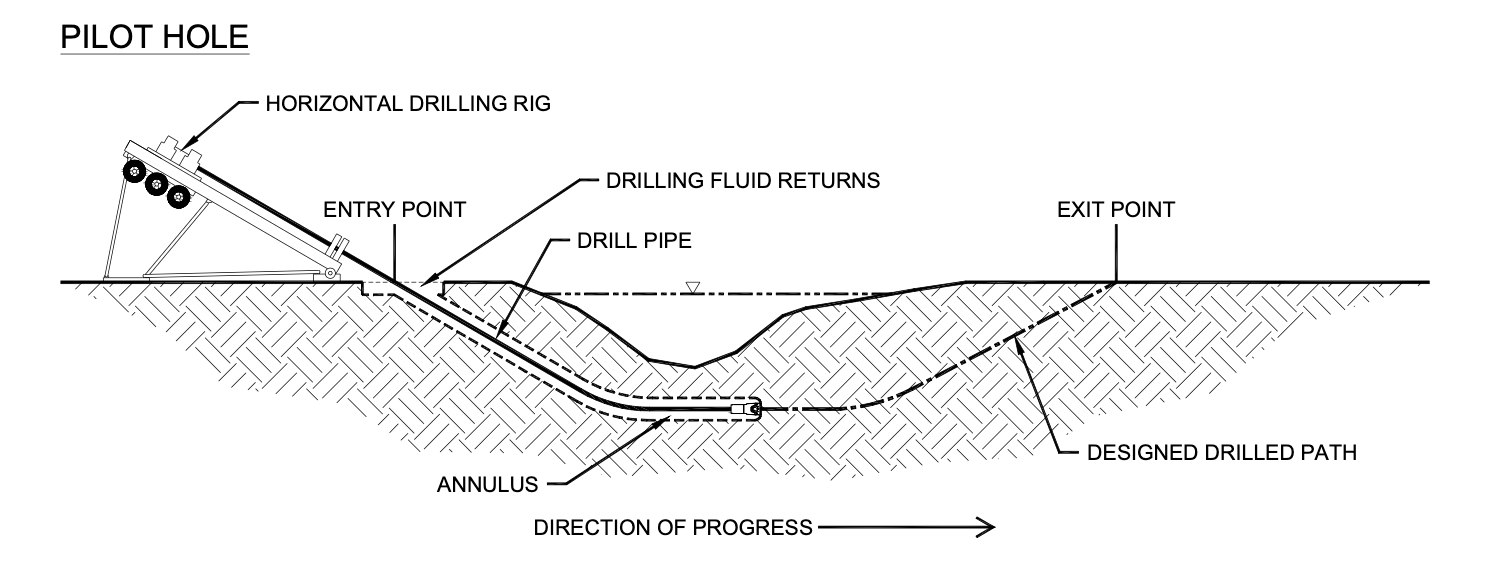

Pilot hole – A steerable drill head bores a small, precise path underground.

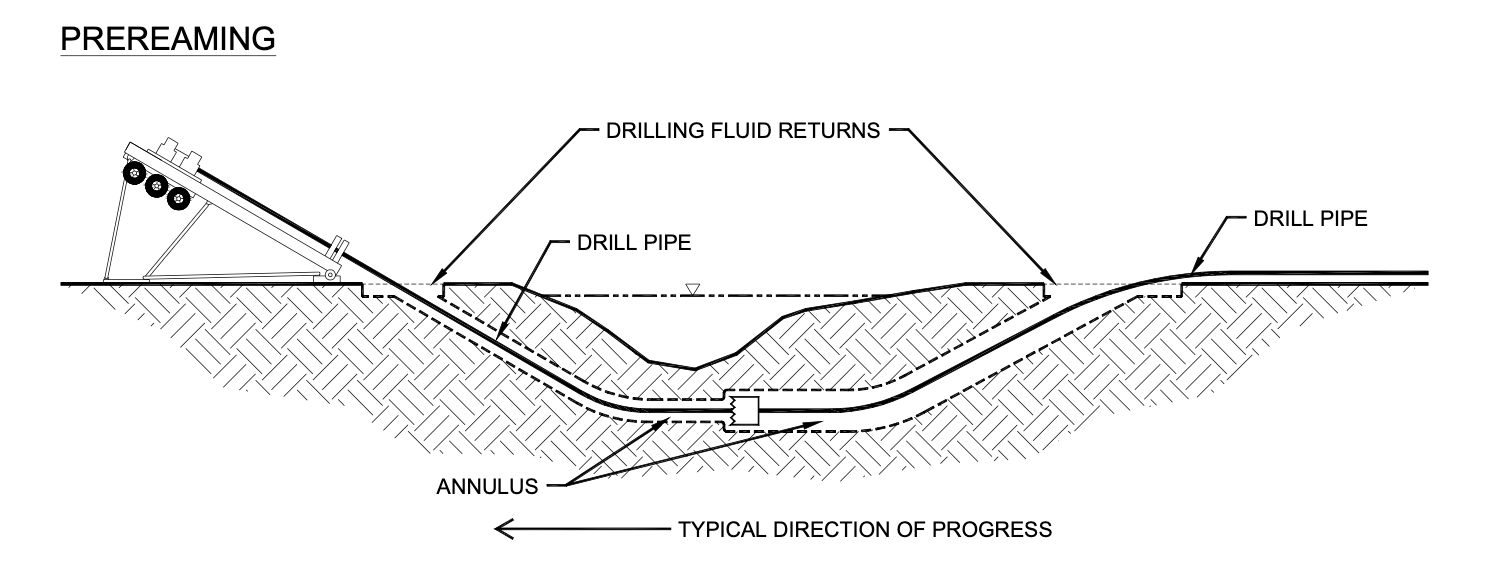

Reaming – The hole is enlarged to the required diameter.

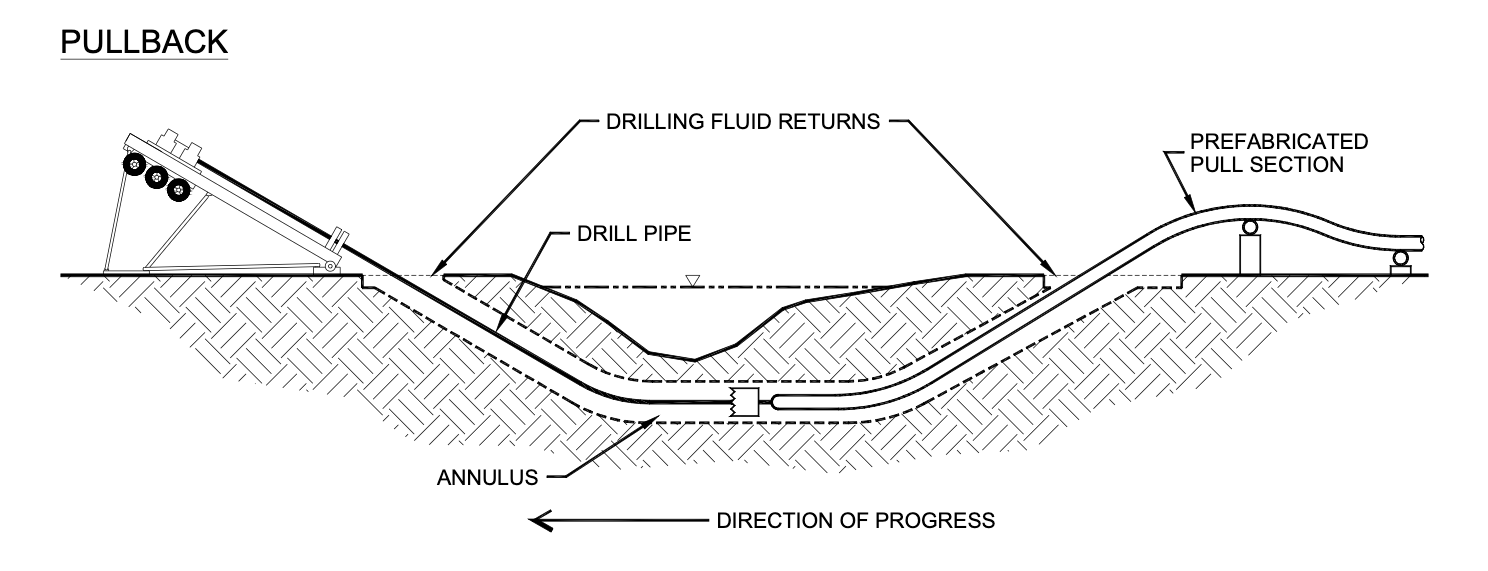

Pullback – The pipe or conduit is pulled back through the finished bore.

Why it’s used

Minimal surface disruption

Faster than open-cut excavation in developed areas

Ideal for crossings under roads, rivers, rail lines, wetlands, and buildings

Reduced environmental and restoration costs

What it installs

Water and sewer mains

Gas and oil pipelines

Electrical and fiber-optic conduits

Key distinction

It’s called “drilling,” not boring, because it uses drilling rigs, drill pipe, steering tools, and drilling fluid—technology adapted from the oil and gas industry.

Pilot Hole Drilling

A small-diameter hole is directionally drilled along a precisely engineered path.

STEP ONEReaming: Hole Enlargement

The pilot hole is progressively enlarged to the required diameter for the pipeline.

STEP TWOPipeline Pullback

The pipeline is pulled back through the enlarged hole into its final position.

STEP THREE